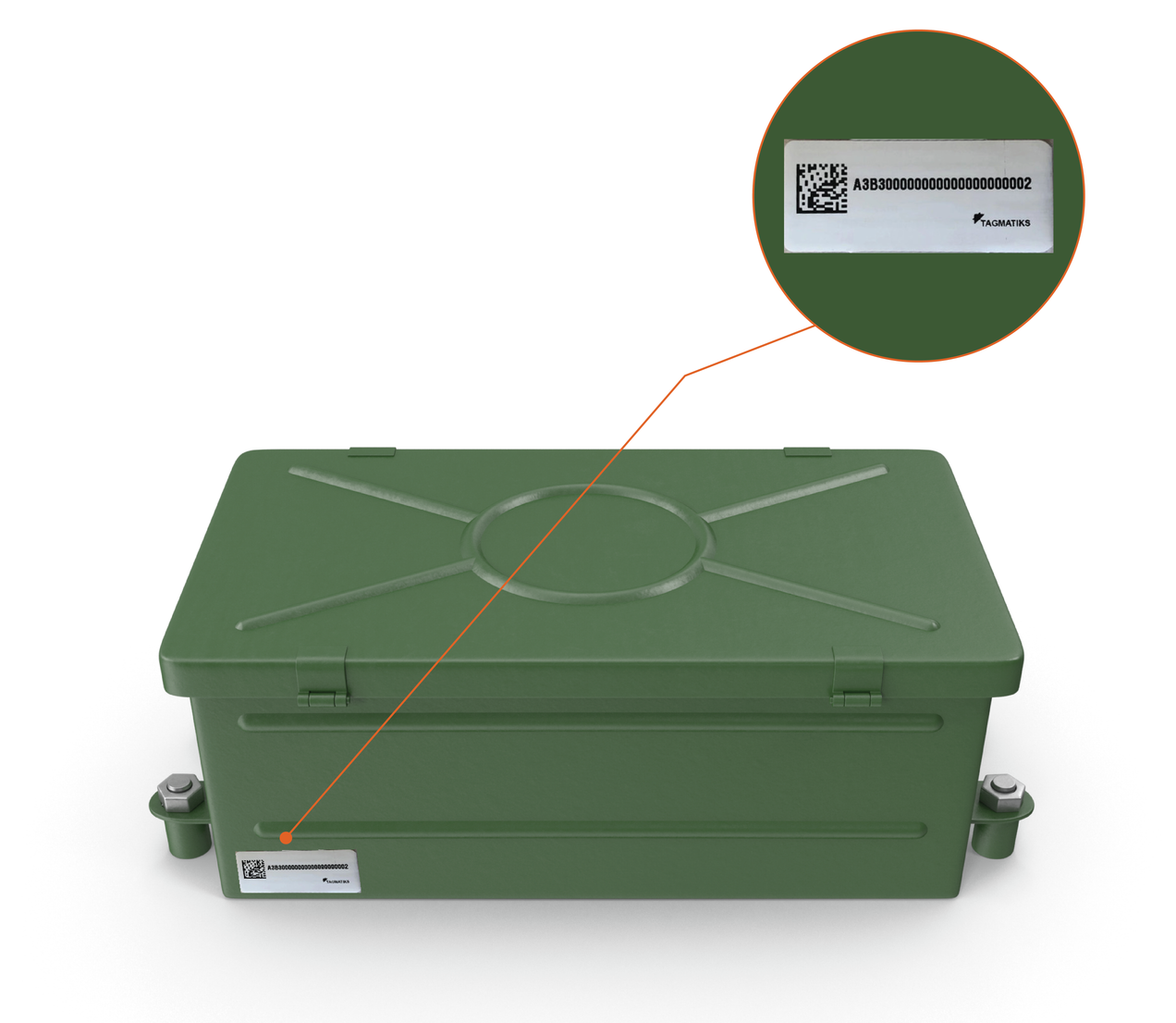

RFID Metal-Mount Tags Used on Metal Surfaces

RFID tags on metal pose a challenge when it comes to the application of RFID technology on metal surfaces. The inherent properties of metal, such as its conductivity and ability to reflect signals, can affect the performance of RFID tags. However, advances in the field have led to the development of on-metal RFID tags specifically designed to overcome these obstacles and enable efficient tracking on metal surfaces. On-metal RFID tags are designed with features that address the challenges posed by metal substrates. These tags typically incorporate shielding materials or unique antenna designs that minimise interference from metal surfaces. These special RFID tags optimise the tag structure. This ensures reliable and accurate data capture even in harsh metal-rich environments.

RFID On Metal Tags Features

An important aspect of RFID tags on metal is their ability to withstand harsh conditions. They are built to withstand the extreme temperatures, humidity and physical effects often encountered in industrial environments. This durability increases their value in a variety of applications, making RFID tags long-lasting and reliable. The versatility of RFID tags on metal is another key advantage. They can be attached to metal assets, equipment or products, enabling seamless tracking throughout the supply chain and production processes. These tags provide real-time visibility and increase operational efficiency.

Furthermore, on-metal RFID tags are relatively simple to integrate with existing systems. They can be easily incorporated into automatic identification and data capture (AIDC) systems. This allows organisations to leverage their existing infrastructure. This seamless integration streamlines processes, reduces manual effort and increases overall productivity. The applications of RFID tags on metal are extensive in a variety of industries. In the automotive sector, these tags play a crucial role in inventory tracking and management, optimising production and facilitating efficient supply chain management. In aerospace and defence, on-metal RFID tags help in asset tracking and maintenance. The healthcare industry uses on-metal RFID tags for asset tracking, patient identification and medication management.

These tags help streamline processes, prevent errors and improve patient safety. In retail and logistics, metal RFID tags provide inventory management, anti-theft and secure supply chain operations. As a result, metal RFID tags have revolutionised tracking and efficiency on metal surfaces. Through custom designs, durability, versatility and easy integration, these tags overcome the challenges presented by metal substrates. As technology continues to advance, RFID tags on metal will continue to evolve. This will unlock new possibilities for seamless tracking and management on metal surfaces.

Labels: rfid, rfid tag, tag, rfid tag, rfid tag on metal, rfid tag on metal, metal tag, rfid reader, rfid tag

August 07, 2023

Return to List