Mold Management System and Tracking with RFID

RFID Mold Management System

Mold Management System and Tracking with RFID

Molds used in the manufacturing sector are critical elements that directly affect efficiency and product quality. Incorrect mold usage, unplanned maintenance processes, or lost molds can cause significant costs for businesses. RFID (Radio Frequency Identification)-based mold management systems prevent these issues by digitizing production processes and increasing operational efficiency.

How Does the RFID Mold Management System Work?

RFID mold management works by placing special RFID tags (hard tags) on each mold, enabling real-time tracking of these molds on the production line. Through RFID readers and network-connected systems, information such as the mold’s location, which production line it is used on, and how long it has been operating is collected in a central software system.

Basic Working Principle:

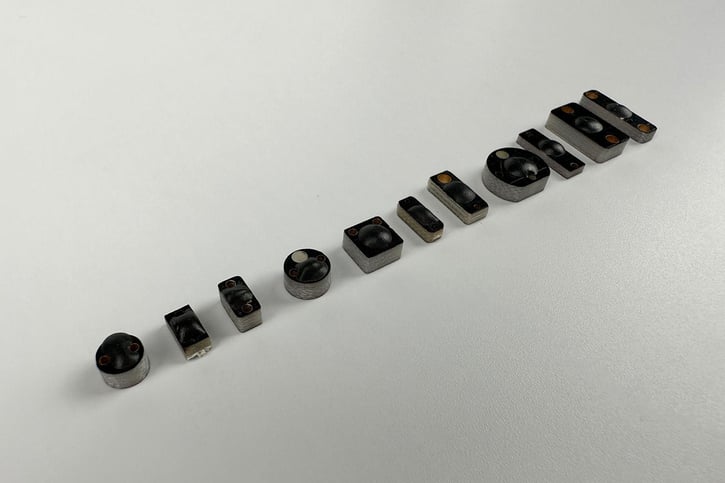

- RFID Hard Tag Application: Durable RFID tags are attached to molds.

- Tracking with RFID Readers: Fixed readers installed on the production line or handheld terminals track mold movements.

- Real-Time Data Flow: Mold status, usage, and maintenance information are transmitted instantly to the system.

- Software Integration: Central management software analyzes data to offer efficient mold usage and maintenance planning.

Advantages of RFID Mold Tracking System

- Prevents Errors: Optimizes production by avoiding incorrect mold usage.

- Reduces Unplanned Downtime: Automatically schedules mold maintenance to prevent sudden failures.

- Increases Efficiency: Tracks mold movements to determine optimal usage periods.

- Simplifies Inventory Management: Enables instant detection of unused or missing molds.

- Enhances Production Safety: Supports workplace safety by preventing incorrect mold handling during forklift and crane operations.

Where Is RFID Mold Management Used?

- Automotive Manufacturing: Optimizes production by monitoring mold lifecycles.

- Plastic Injection: Ensures correct usage of molds for different products.

- Metal Processing: Facilitates transportation and tracking of heavy industrial molds.

- White Goods Manufacturing: Speeds up mold changeover processes to shorten production time.

RFID mold management creates a faster, more reliable, and efficient structure in manufacturing processes. This technology reduces costs for businesses and is an important part of automation and digital transformation. By making production lines smart with RFID solutions, it is possible to establish a continuous and efficient manufacturing model.

Labels: Industrial Mold Management, Mold Tracking System, RFID Mold Tracking, Smart Manufacturing, Industry 4.0, Mold Management System, Production Tracking, Automotive Mold Tracking, Plastic Injection, Metal Injection, IoT Mold Management, Factory Automation, Efficient Production, Smart Mold Management.

May 28, 2025

Return to List